Digital Twins: Transforming Chemical Plants Operations with IoT

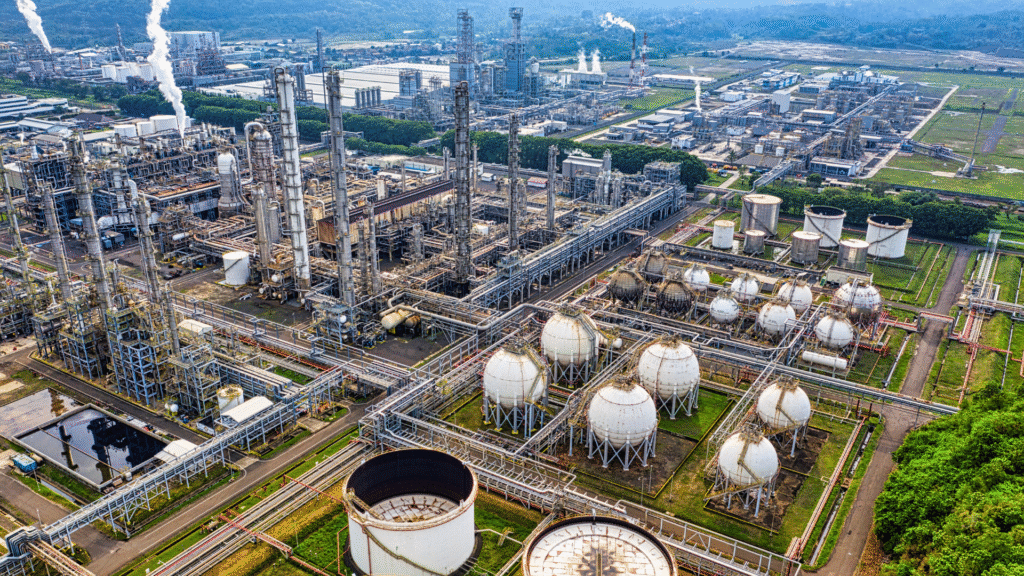

Digital Twins and Internet of Things (IoT) are changing the way we think about chemical plant optimization. Imagine a virtual model of a chemical plant where you can play around and figure out how to make everything run smoother. That’s what digital twins do! They use real-time data from tons of sensors to show you exactly what’s happening inside the plant.

Smart chemical manufacturing is now possible with these digital models. Digital twins chemical plants help make operations safer, cut down waste, and boost efficiency. Also, they spot problems before they happen, saving time and money.

In this journey, find out how digital twins and IoT work together to create a smarter, safer, and more efficient world in chemical manufacturing. It’s a bright future, and you’re invited to be a part of it!

Understanding Digital Twins and IoT in Chemical Plants

What are Digital Twins?

Virtual Replicas of Chemical Plants

Digital Twins are like magic mirrors for chemical plants. Imagine a virtual copy of a plant that exists in your computer. It’s just like the real plant but lives in a digital world. You can see everything that happens inside the plant without being there. It helps designers and engineers plan what to do next. This virtual plant looks at how the real machines and tools work and acts just like them.

How They Function with Real-Time Data

Digital Twins come alive with real-time data. They use information from the actual tools and machines in the plant. Through this data, the clone knows what’s happening right now, just like the real plant. Sensors on equipment collect data and send it to the digital twin. This way, if something goes wrong, we know right away and can fix it fast. By using this info, the virtual copy ensures the plant keeps running smoothly.

The Role of IoT in Chemical Manufacturing

Sensor Networks and Data Collection

In every corner of a chemical plant, there are tiny gadgets called sensors. These act like the plant’s eyes and ears. They gather information about temperature, pressure, and more. Think of them as hard-working bees collecting honey, only these sensors are collecting data. They make sure everything is running as it should. The data they gather is sent to the digital twin, which uses this info to understand what’s happening in the plant at any moment.

Secure Data Transmission

Once all the data is collected, it has to be shared safely. Secure data transmission is like sending a treasure map across the world without letting anyone else see it. It’s important that only the right people and systems see the data. Special ways are used to make sure it stays secret and gets to the right place without anyone changing it. This secure path ensures that the digital twin receives the most accurate and up-to-date information to keep everything running well.

How Digital Twins Optimize Plant Operations

Digital Twins make plants run like well-oiled machines. By using these virtual models, chemical plants can work better, faster, and safer. Let’s dive into how these nifty tools make everything more efficient.

Predictive Maintenance and Downtime Reduction

Digital Twins are like having a superpower to spot problems before they happen.

Identifying Anomalies Early

Machines can act funny sometimes, and Digital Twins help us catch those quirks early. By keeping an eye on real-time data, these twins can see when things aren’t working as they should. It’s like having a warning sign before the smoke comes out.

Estimating Remaining Equipment Lifespan

Ever wondered how long your favorite pair of shoes will last? Digital Twins do the same for machines. They help predict how much life is left in your equipment. Knowing this helps in planning when to fix or replace parts, so the plant stays up and running without a hitch.

Improving Process Efficiency and Yield

Getting the most from what you have is important, and Digital Twins are pros at this!

Energy Efficiency Measures

Plants use a lot of energy, and it’s crucial to save wherever possible. Digital Twins help find ways to use energy smarter, cutting costs and being kinder to the planet.

Maximizing Product Output

Who doesn’t like getting a little extra? Digital Twins work to boost the plant’s output so that every bit of material turns into valuable product. It’s like squeezing every last drop out of a lemon!

Safety Enhancements and Risk Mitigation

Safety is number one, and Digital Twins make sure everything stays safe and sound.

Simulating Hazards

Before anything dangerous happens, Digital Twins can run through ‘what if’ scenarios. They simulate potential hazards so solutions are in place before any real troubles show up.

Leak Detection Mechanisms

Leaks can be sneaky, but not with Digital Twins. These twins have a keen sense for spotting leaks early, keeping everyone and everything protected from harm.

Boosting Quality Control

Nobody wants a faulty product. Digital Twins help maintain top-notch quality by keeping an eye on every stage of production. This means fewer errors and happier customers!

In summation, Digital Twins are incredible helpers in making chemical plants more productive, safer, and efficient. They turn complicated challenges into manageable problems, ensuring everything runs smoothly and safely.

Exploring Smart Chemical Manufacturing

In the world of smart chemical manufacturing, technology is a game-changer. It’s like having a magic wand that makes everything run smoother and better. Let’s dive in and see how this works!

Benefits of Flexible and Agile Production

Flexible and agile production is a big deal in chemical plants. Imagine a factory that can quickly change what it makes based on what people need. Flexible production allows companies to make the right products at the right time without wasting resources. This flexibility helps companies stay ahead of the competition and keep their customers happy.

Implementing Sustainable Practices

Manufacturers need to take care of our planet while making their products. Sustainable practices are like super helpful habits that save energy and reduce waste.

Resource Optimization Strategies

Resource optimization means using only what you need. Companies use smart systems to track how much energy or materials they use. By doing this, they can cut down on unnecessary use. It’s like turning off the lights when you leave a room – simple, but it saves a lot!

Waste Reduction Techniques

No one likes waste, right? Waste reduction techniques help factories make less trash. Factories use smart ways to recycle and reuse materials, turning waste into something useful. It’s like giving trash a second chance!

Collaborative Manufacturing Processes

Collaborative manufacturing means working together with other factories and teams. By sharing ideas and tools, companies make better products faster. In this teamwork, technology helps everyone stay connected and informed. It’s like a big group project where everyone shares the load and wins together!

AI-Driven Automation in Manufacturing

AI-driven automation is like having robots that think. These smart helpers can do dangerous or boring tasks, making factories safer and faster. Automation means machines do things all by themselves, with AI guiding them. This makes sure everything is done just right and on time.

In smart chemical manufacturing, each part works like a piece of a puzzle. When every piece fits perfectly, manufacturing becomes seamless, efficient, and earth-friendly.

Challenges in Implementing Digital Twins and IoT

Let’s take a look at some of the biggest challenges when implementing Digital Twins and IoT in chemical plants. These challenges can feel like untangling a ball of yarn, but they are super important to think about.

Data Security and Privacy Concerns

Data security is like keeping a secret. When chemical plants start using Digital Twins and IoT, they collect a lot of data. This data needs to be kept safe from hackers. Protecting this information is like putting it in a vault. Ensuring data privacy means making sure that people only see the information they are supposed to see.

Integration with Existing Systems

Integration is about making things fit together like puzzle pieces. Many chemical plants already have systems in place. Adding new technology like Digital Twins and IoT might not fit perfectly. It’s like adding new gears to an old clock. We have to figure out how to make everything work together smoothly.

Addressing Skill Gaps

Skill gaps are like missing tools in a toolbox. Not everyone knows how to use Digital Twins and IoT right away. Workers might need to learn new things, and teaching them can take time. It’s important to make sure they have the right skills to keep things running well.

Evaluating Initial Investments and ROI

Initial investment feels like saving up for a big toy. Before spending money on new tech, plants need to think about how much it will cost. ROI, or return on investment, is about knowing if it’s worth the money spent. It’s like deciding if buying new tech will bring good results or if we should just keep using the old stuff.

Understanding these challenges can help chemical plants make better decisions. It’s like planning a trip; the more you know, the smoother the journey will be!

Future Trends in Chemical Plant Technology

Autonomous Plants Powered by AI

Autonomous Plants are like magic. With the help of AI, these plants can almost run themselves. They use high-tech tools that think for them. Sensors watch over everything, making sure the machines work just right. Thanks to the smart brains of AI, they spot problems early and fix them before anything goes wrong. This makes the plant work better and keeps it safe.

Blockchain for Transparent Supply Chains

Blockchain is like a digital notebook everyone can see, but no one can change. For chemical plants, it means knowing exactly where things come from and where they go. Every step of the way is clear as day. With blockchain, you see everything in the supply chain. It’s all about trust and keeping everything fair and square.

The Role of Edge AI and 5G

Edge AI and 5G are like a superhero duo. Edge AI brings smart thinking close to where things happen. This quick thinking helps machines react almost in the blink of an eye. 5G is the super-fast internet that helps machines talk to each other very quickly. Together, they make sure every part of the plant is always in sync. No more waiting around. Everything moves fast and smooth.

Sustainability and Circular Economies

Sustainability is about taking care of our world. In chemical plants, it means using only what they need and wasting as little as possible. Circular economies go a step more by reusing things over and over again. It’s like recycling but much bigger. By using tools like digital twins, plants can see the best ways to save energy and cut waste. It’s smart and kind to the Earth.

Quantum Computing in Chemical Processes

Quantum Computing sounds like something from a sci-fi movie. It uses tiny particles to think in ways that normal computers can’t. For chemical plants, this means solving really hard problems super fast. Quantum computers might help create new materials or make tricky chemical reactions happen. They’re a key that opens up big new possibilities for plant operations.

These new trends are set to change the face of chemical manufacturing. They’re all about making things faster, smarter, and better for everyone and the planet.

Ethical Considerations in Technology Integration

In the world of technology, as we make things faster and better, it’s super important to think about how these improvements affect people and the planet. Let’s dive into some key areas we need to be mindful of.

Job Displacement through Automation

When we talk about automation, it means using machines instead of people to do tasks. This is great because it makes things faster and sometimes cheaper. But it also means that some people might lose their jobs. For example, if machines can do all the work on a factory floor, the workers might no longer have jobs to do.

- Impact on Workers: Automation can be scary because it makes some jobs disappear. People who are used to working in factories may find it hard to get new jobs.

- Learning New Skills: To help, it’s important for workers to learn new skills. This way, they can work with the machines instead of being replaced by them.

Ensuring Data Privacy

Data privacy is all about keeping people’s information safe and secure. When companies use digital systems, they collect lots of information about people and processes.

- Protecting Information: Companies need to make sure that the information they collect about people doesn’t get into the wrong hands. This means keeping data secure from hackers and not sharing it without permission.

- Transparency: People should know how their data is being used. Companies should explain what they’re doing with your information and why.

Environmental Responsibilities

Technology can also have a big impact on the environment. As we create new systems and machines, we need to think about how they affect our planet.

- Energy Use: Machines and computers often need a lot of energy. We should aim to use energy that doesn’t harm the environment, like solar or wind power.

- Reducing Waste: Making sure waste is reduced can help keep our planet clean. This means reusing materials and recycling whenever possible.

It’s key for us to put the planet first while also taking care of the people who build and work with these technologies.

By thinking about these ethical considerations, we can make sure that technology helps everyone, not just a few people. It’s about finding a balance between making things better and doing what’s right for everyone.

One comment

Comments are closed.

[…] Digital twins are virtual replicas of physical systems, utilized to simulate and optimize chemical processes before actual implementation. By mirroring production environments digitally, companies can test and refine processes, predict outcomes, and assess the impact of changes without physical trials. This minimizes emissions and waste, as potential inefficiencies and environmental impacts are addressed in the digital realm preemptively. […]